Do your LED strip lights keep falling off when you install them? So, it is very important to choose the right double sided tape to ensure that the LED strip lights stick firmly to the surface.

With so many different types of double-sided tape on the market, it can be difficult to determine which one is right for your needs. In this article, we’ll take a closer look at some of the most popular double-sided tapes for LED strip lights, and how to choose the right one for your project.

Standard Double Sides Tape for LED Strip Lights

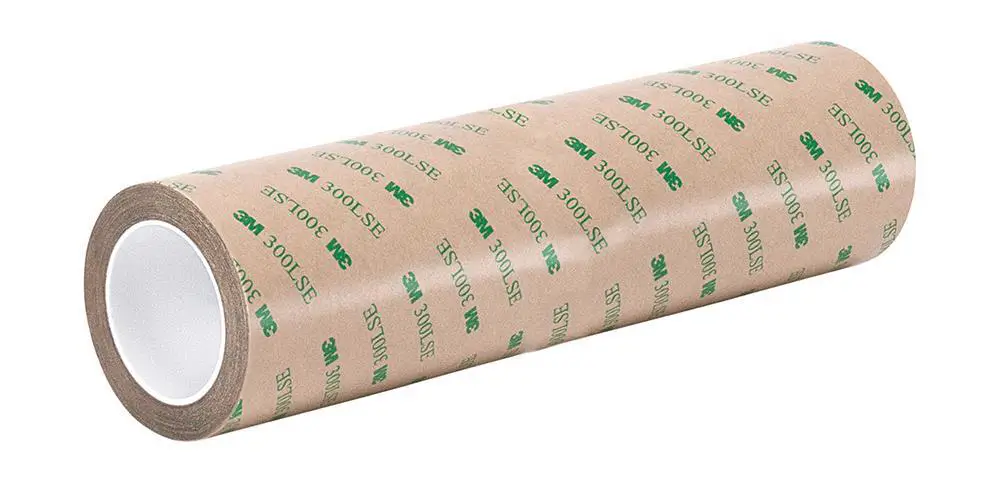

Most LED strip brands and manufacturers use 3M adhesive backing, but 3M makes various versions of 3M adhesive. Its quality and cost are also different. Generally, 300LSE is the most used LED strip light, which is very suitable for use on surfaces.

- 3M 200MP

- 3M 300MP

- 3M VHB 5608N

- Blue thermal tape

3M 200MP

3M 200MP is a popular double-sided tape that is ideal for LED light strips. Because of its excellent quality and durability, it also has excellent adhesive properties and can withstand high temperatures and humidity. This tape is great for use on smooth surfaces like glass, metal, and plastic.

3M 300MP

The 3M 300MP is another popular double-sided tape for LED strip lights. It has similar properties to the 200MP tape but is slightly thicker and more durable. This tape is ideal for use on rough or uneven surfaces like wood, concrete, and brick.

3M VHB

3M VHB is a high strength double sided tape ideal for LED strip lights. It has excellent adhesive properties and can withstand extremes of temperature and humidity. This tape is great for use on rough or uneven surfaces such as wood, concrete, and brick.

For example, 3M VHB 5608 is characterized by high adhesion to various automotive surfaces. One side of the tape is attached to the painted surface or corresponding substrate with a pressure-sensitive adhesive. The other side is bonded to the elastomer part by heat activation

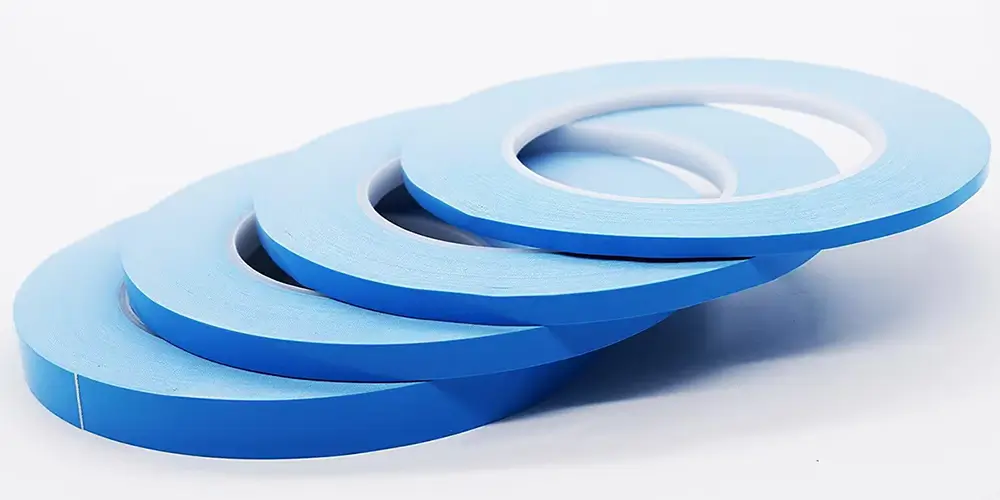

Blue Thermal Tape

Blue thermal tape is another option for attaching LED strip lights. It has strong adhesive properties and can withstand high temperatures. This tape is ideal for use on heat-sensitive surfaces like plastic and polycarbonate.

Different tape come with different characteristics and they are better suited for different surfaces. Therefore, when choosing double sided tape for LED strip lights, it is important to consider the surface to which the tape will be applied. Also, it is important to consider the strength and durability of the tape.

What Kind of Double Sided Tape is Best for LED Strip Lights?

The best double sided tape for LED strip lights is 3M VHB (Very High Bond) tape, but 300LSE back adhesive is enough if there is no special requirement. It comes in a variety of lengths and widths and is easy to cut to size. This tape can be used as a supplement to the original adhesive backing on rolls of LED strip lights.

But it should be noted that 3M VHB double-sided tape is super strong. The longer it sticks, the more likely it is to damage paint, drywall (slate), wood, veneer, and all kinds of surfaces if you try to remove it.

How to Add Double Sided Tape to LED Strip Light?

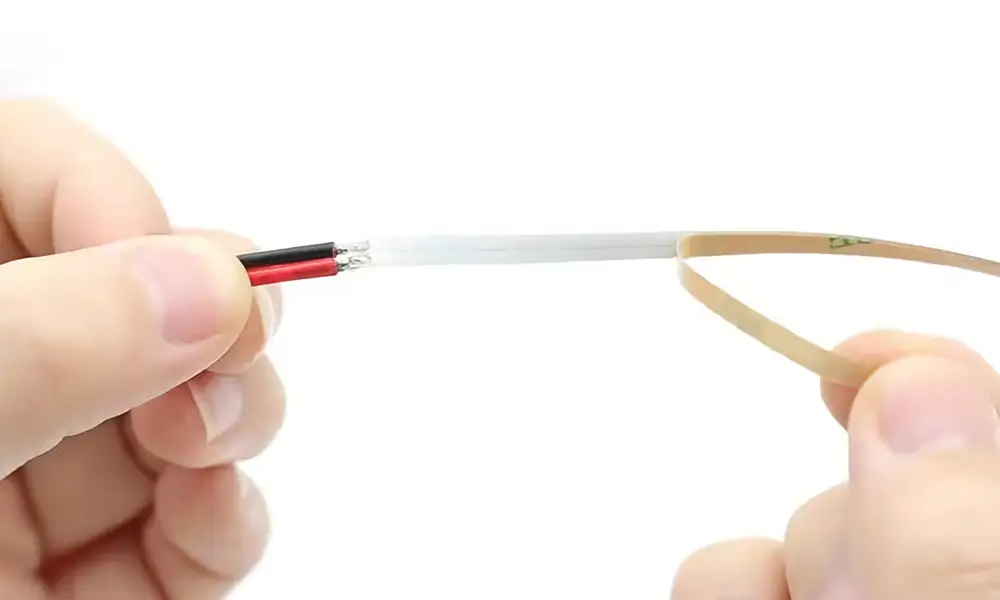

Once you find that your LED strip is likely to come off or need some extra double sided tape to be more secure, you’ll need to add it to your LED strip.

- Find the Right Size Double Sided Tape

First of all, we need to confirm the size of the LED strip, and then find the double-sided tape of the same size. - Cut the double-sided tape to the length of the LED strip.

The best way to do this is in sections, cutting the double sided tape into easy-to-handle size. This makes it easy to adhere to the adhesive already on the light strip. - Properly adheres to the LED strip lights

Once your double sided tape section is cut, apply the tape to the back of the LED strip, making sure to apply evenly, and remove the backing from the other side of the tape. - Gently press the LED strip lights

Place the LED strip lights on the surface, making sure to apply pressure evenly along the entire length of the strip so that the double sided tape becomes one piece with the LED strip lights.

How to Prepare Surfaces for LED Strip Lights?

Preparing the surface is one of the most important parts of the light strip installation process, we need to make sure it is credential dry. Any existing debris or dust will interfere with proper adhesion to the surface.

- Make sure to adhere the light strip to a dry, clean, and smooth surface.

- For most surfaces, clean the surface with rubbing alcohol to remove any dirt or debris. and let dry.

- If it is cold below 50°F/10°C, use a hair dryer to heat the adhesive.

- To create a stronger bond, before applying, turn on the LED light to create a heat bond between the double sided tape and the led strip lights.

- Remove the protective film (usually red).

- Slowly adhere the light strip to the surface, moving from side to side.

Conclusion

It stands to reason that if it is high-quality 3M double-sided tape, the stickier it gets, the harder it is to tear off. Choosing the right double-sided tape for your LED strip lights is important to ensure they stick securely to surfaces.

The best tape depends on your specific needs and requirements, as well as the type of surface your LED strips are attached to and the level of strength and temperature resistance you need. You will need to do a lot of testing to find the best tape for your particular application.

FAQs

The strength and adhesive properties of the tape, as well as its compatibility with your LED strip lights and the surface you’re attaching them to.

3M 300MP Tape is another double sided tape that is similar to 200MP Tape but has higher adhesion and shear strength. Conventional LED strip lights can use this double-sided adhesive.

Simply cut the tape to the desired length, peel off the backing, and apply it to the back of the LED strip light. Then, remove the second backing and attach the LED strip light to your desired surface.

Make sure the surface is clean and free of dirt, dust, or any other contaminants that may affect the tape’s adhesion. You may also want to use an alcohol wipe to clean the surface before applying the tape.

The best tape depends on your specific needs and requirements, such as the type of surface you’re attaching the LED strip lights to and the level of strength and temperature resistance you need. It’s recommended to do some research and read reviews to find the best tape for your specific application.