In lighting solutions, achieving consistent color output from lamps is crucial to the user’s visual effect and the overall LED lighting effect. LED technology is an innovative lighting technology, but confirming color consistency can be very challenging. Because of various factors such as manufacturing differences and environmental conditions.

This article delves into the concept and importance of LED color consistency, explores correlated color temperature (CCT), discusses the relationship between color temperature consistency and the MacAdam ellipse, and provides tips for achieving and controlling color consistency in LED lighting applications insights.

What is Color Consistency?

LED color consistency refers to the uniformity of color output among multiple LED light sources. LEDs with the same specifications of light sources need to produce consistent colors, which can ensure uniform lighting and eliminate visual differences.

For example, the blue/yellow difference can be characterized using color temperature (measured in degrees Kelvin). Acceptable color variation depends on your lighting application, but +/-75K is typically the threshold for noticeable color difference for warm whites, and +/-150K for normal or cool whites.

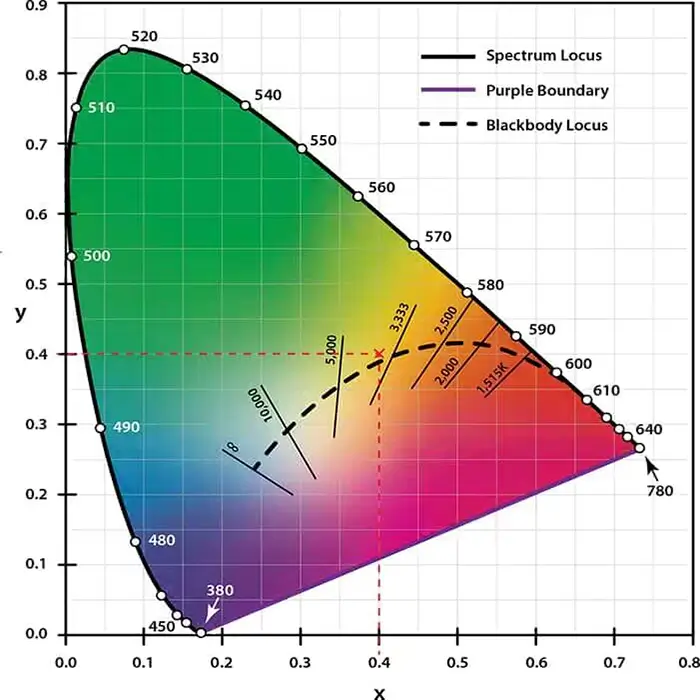

Color temperature (CCT) is a metric used to describe the color appearance of light emitted by an LED light source. It is measured in Kelvin (K) and represents the perceived warmth or coolness of light. LEDs with lower CCT values emit warm white light, while LEDs with higher CCT values emit cool white light.

What is the Relationship Between Color Temperature and MacAdam Ellipse?

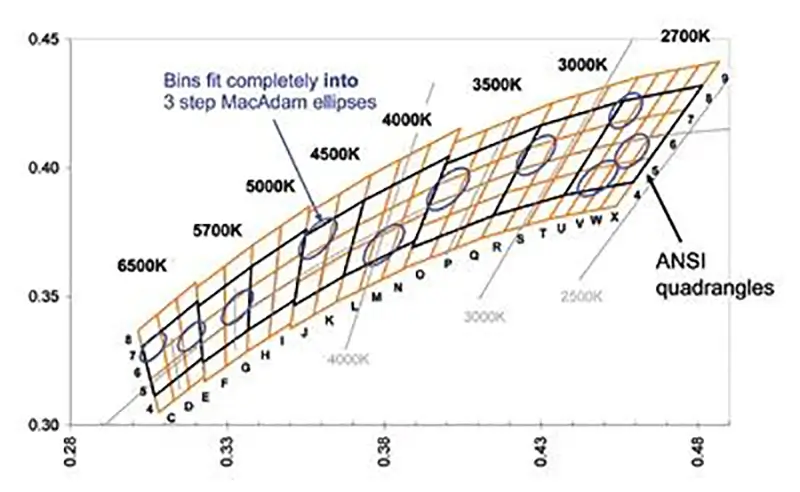

The MacAdam ellipse is a graphical representation of the color change around a reference point. For example, if a color temperature is 3000K, some manufacturers have 8 boxes to represent it. There will always be specific changes in Duv fluctuations and K degrees between each 3000K barrel.

LEDs with smaller MacAdam ellipses exhibit tighter color consistency because they deviate less from the reference color. Color temperature plays a crucial role in determining the size of the MacAdam ellipse, with smaller deviations indicating better color consistency.

What is the Normal Color Temperature Difference Allowed?

The tolerance or variation area of LED color temperature corresponds to each point. These changes are measured along the curve of Calvin’s black body, and the curve of vertical fluctuations is called a Douv. The CCT types allowed at each color temperature in the color scale are defined by square, vertical and curved lengths.

For example, a nominal CCT of 2700 K squared has a tolerance difference of plus or minus 175 K and is centered at 2745 K. 2700K square covers the blackbody curve from 2570 K to 2920 K. In reality, the measured Duv and CCT of an LED can vary significantly, but we can still call it 2700K CCT.

How to Achieve LED Consistent Color?

During the LED production process, LED lumens, voltage, and color temperature will vary. Achieving consistent color in LED lighting requires meticulous attention to detail throughout the manufacturing process.

- Choose LED chips with consistent color grading

- Implement precise phosphor coating technology

- Manufacturers employ strict quality control measures to minimize variation.

How Does Essenled Control the Color Consistency of LED Strip Lights?

At Essenled, Our LED strip lights adopt advanced manufacturing technology and strict quality control processes. Users must prioritize color temperature consistency of LED strips. Our LEDs are rigorously tested to ensure they meet strict color temperature and color rendering standards, resulting in uniform and reliable lighting performance.

Summary

Consistent color is crucial to creating a visually pleasing lighting environment. LED lighting technology has obvious advantages in achieving this goal. By understanding the principles of LED color consistency (such as correlated color temperature and MacAdam ellipse) and implementing robust manufacturing processes, lighting manufacturers can deliver high-quality LED products with uniform color output. At Essenled, we always strive to provide our customers with LED light strips with superior color consistency and reliability.

FAQs

LED color consistency refers to the uniformity of color output among multiple LED light sources. At first glance, the color temperature is consistent and harmonious. This is critical because inconsistent colors can cause visual discomfort and aesthetic issues in lighting applications.

There are many issues that can affect LED color temperature inconsistency. For example, factors such as LED binning, phosphor composition, thermal management, and environmental conditions can affect LED color consistency. To ensure color temperature consistency, we need to pay attention to details in production.

Yes. Manufacturers go through appropriate design, manufacturing and quality control processes. LED lights maintain color consistency over time.

The power supply can affect color temperature consistency. Because the LED driver regulates the current supplied to the LED. Different currents will also affect the color change and overall performance of the LED.

Yes, we cand do it. Generally, there are integrating sphere tests, colorimeters, spectrophotometers, and other specialized test equipment to measure LED color consistency to verify compliance with industry standards.