One of the advantages of the LED strip is that it can be cut and supports custom length. Because the installation project and location are different, you can’t buy the right length of the light strip every time. So users often ask whether the led strip lights can be cut to a fixed length. It will also be asked whether the led strip lights can still be used normally after being cut.

Generally speaking, if the led strip has a cutting line or mark, it can be cut; If not, it is best not to cut it. In this guide, we will solute the main questions about cut LED strip light length.

Can You Cut LED Strip Lights?

Yes, you can cut LED strip lights. Generally, there will be a cut mark on the PCB board of the led strip, a dotted black line, etc. So if your led strip has an obvious cut line, it’s usually safe to cut.

How to Cut LED Strip Lights

Before cutting the strip light, make sure that the led strip you buy can be cut. Otherwise, the cut led strip lights may not be usable. At the same time, you must remember to disconnect the power first. It is very dangerous if you directly cut the led strip lights connected to the power supply.

Measure the Installed Length

Regularly 5 meters/reel for usual. If the LED strip you purchased is too long, you need to cut off the excess part. You need to measure the correct installation length, otherwise, the strip lights are cut too short or too long, which will affect your installation.

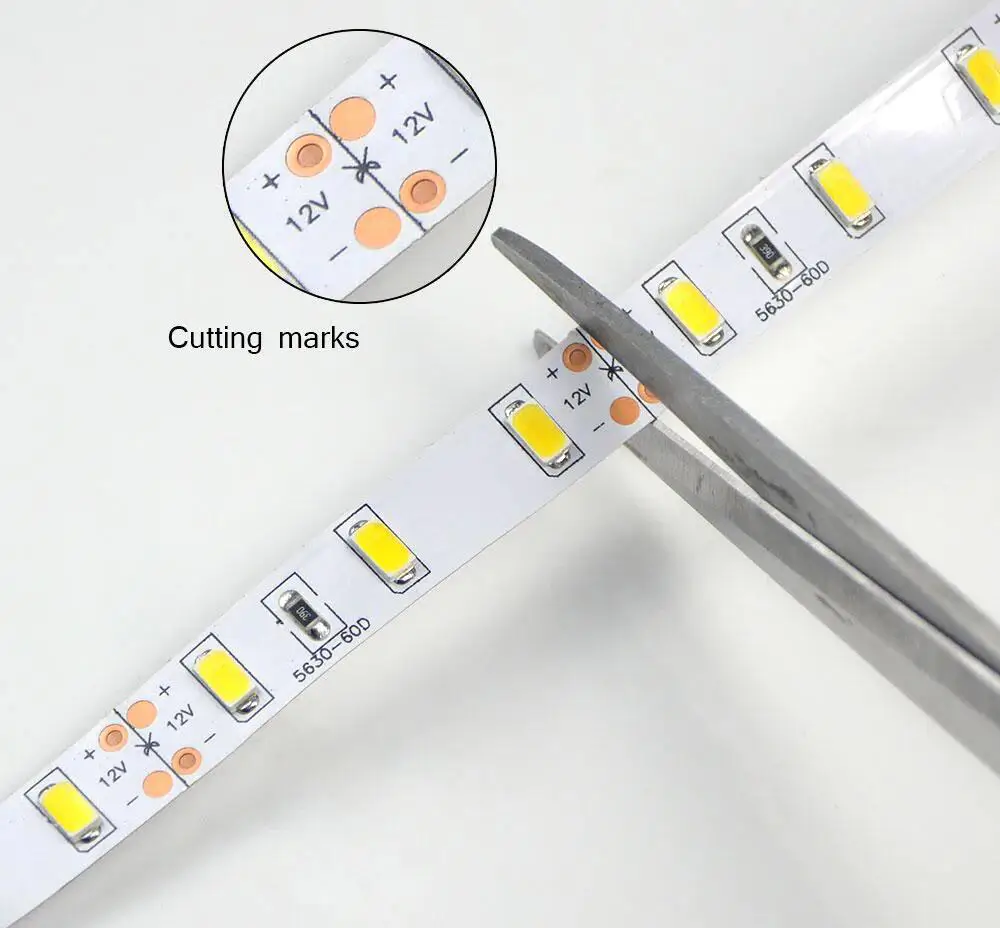

Carefully Note Cut Mark on The LED Strip Lights

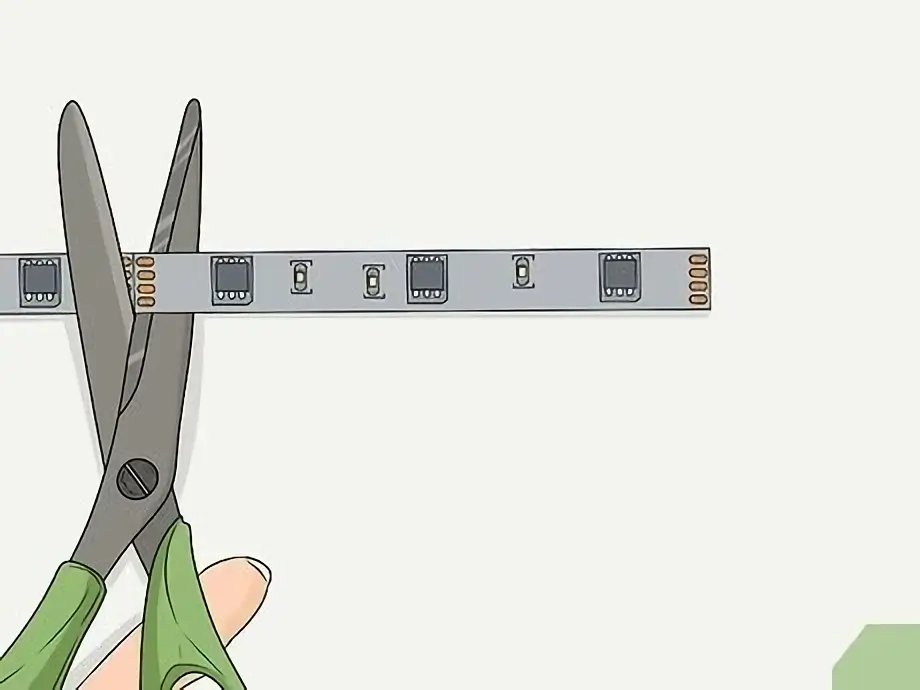

LED light strips are marked with a scissor’s logo or a black dotted line. Before cutting, to avoid damage, be sure to find a suitable location.

Cut Where the LED Strip Lights Were Cut

The final step is to use scissors to cut the led strip lights along the marked locations. Be sure not to cut obliquely as this will cause the light to stop working, so make sure to cut straight.

When You Cut LED Strip Lights Will Both Sides Work?

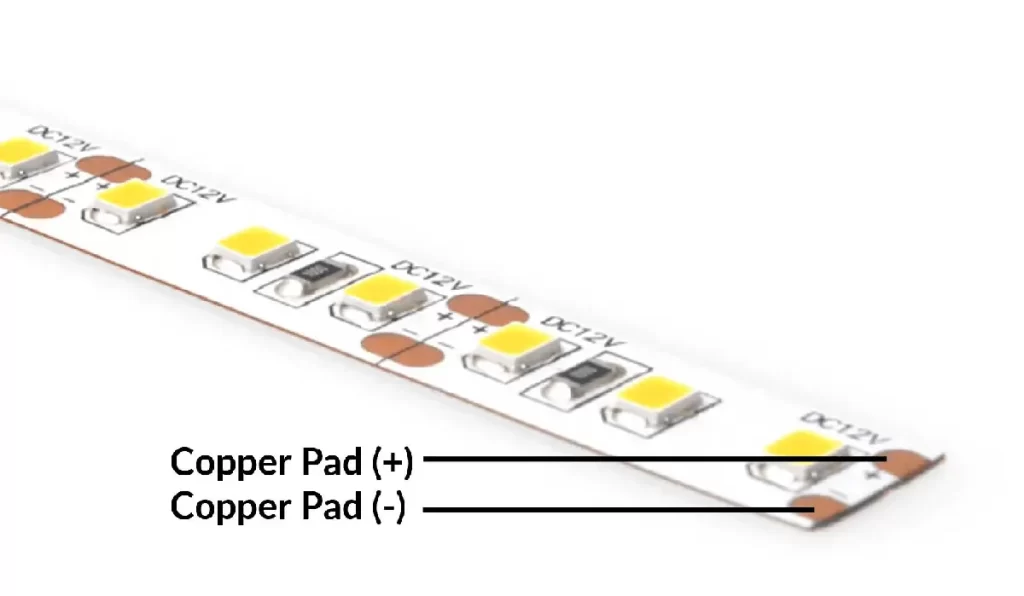

LED Strip on both sides will normally work if you cut from the correct mark and reconnect the correct polarity. Each section between the cutting points of the light strip is a separate circuit, so you need to measure the length of the light strip to determine where you cut it.

Do the LED Strip Lights Don’t Work After Cutting?

If you cut the light strip and they don’t light up. The first thing to do is to check the connection where you cut it. Make sure you cut it correctly. Whether you use re-soldered wires or connectors, you should check that the connections are correct.

Here are some key points to troubleshoot:

Check for loose connections

Make sure the polarity is correct (+ to +)

Leave enough copper on the cutout for connections on each side

Ensure your lights have power

What If I Cut the LED strip Lights In The Wrong Place?

When we open one reel of LED strip, you’ll find cut areas (with scissor cut marks – sometimes with dotted lines – sometimes with black solid lines). Cutting lines exist in designated areas for a reason. Each zone provides an option to limit the circuit (ie, the electrical “circuit” that will be completed when the cut zone is terminated).

If cut in the wrong place, this will end the electrical loop intermediate circuit. The power supply will not light any LEDs on the strip between the last cut area and the cut you made. To avoid this problem, always the cut place the cutout area provided.

How to Reconnect Cut LED strip lights?

In fact, there are several ways to choose, but the most efficient and direct way is to directly weld the wire, or connect the quick connector.

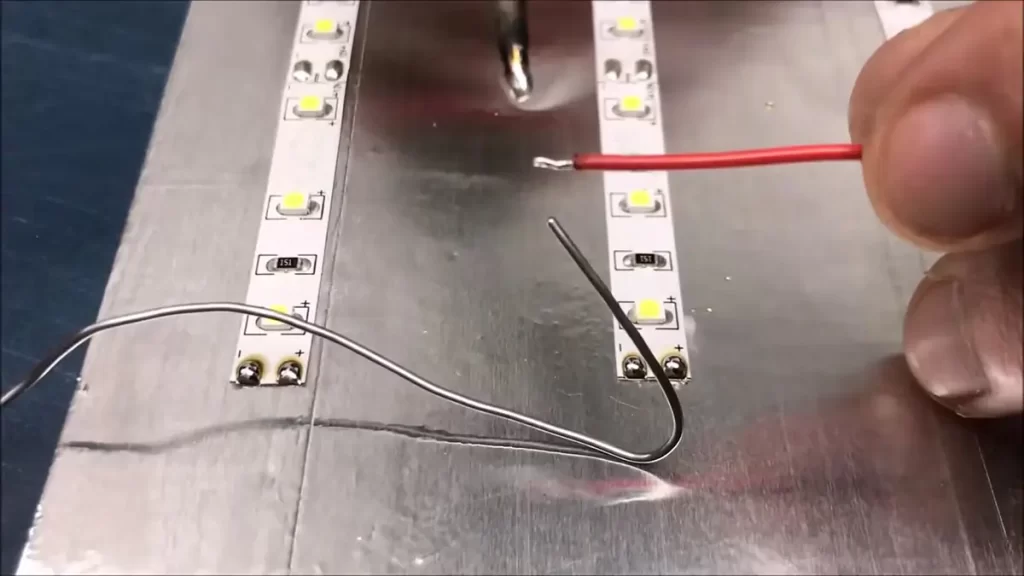

Welding Wire

The most straightforward and efficient way is to use a soldering iron and old wire to solder directly to the strip. You can melt the solder directly onto the copper point, making a little puddle and aligning the positive and negative terminals. The black line should line up with the negative mark and the red line should line up with the positive mark. The benefit of soldering your LED strip to the connecter is that you ensure a join that cannot easily come loose.

Use a Connector

Of course, when you don’t have access to a soldering iron. We have a choice of connectors. There are connectors for light strips to light strips, and light strips with wires for your choice. Because they do not require any tools. You need to choose the correct connector. Cut in the correct location first, then insert the strip into the connector, making sure the components match.

Conclusion

LED light strips can be customized to fit the requirements of any installation. So it’s important to know everything you need to know about light strips before buying one. In addition, if it is not convenient for you to cut by yourself, or the quantity is too large, you can directly customize the length of the light strip.

Also, have you tried cutting LED strip lights? Do you prefer to use a soldering wire or a connector? I’m curious to know which solution is preferred.

FAQs

Our regular led strip lights 5meter/reel, and we support customizing the length of the light bar without any MOQ. If you need to customize the length of the light bar, you need to tell us in advance.

No, you need to cut at the specified cutting position. If you don’t, you could damage the light strip itself as well as the components on the circuit board.

Simply put – very easy. It just involves using a normal pair of scissors and cutting across the designated cut point. Honestly, it’s that easy.

Cutting points are marked by scissors, or a thin line, with a set of metallic solder points on either side.

Of course, You just need to cut the light strip with scissors in the right place.